Case Studies

Rechargeable Battery Component Manufacturer Struggled to Find Right Feeder for New Factory

Industry:

Rechargeable battery component manufacture

Department:

Production engineering

Support from feeder specialist promised reduced overall costs.

Summary of the solution

The revolutionary design of Kubota’s NX series of gravimetric feeders enabled highly-precise dosing.

The NX series’ simple design and small number parts made for simpler maintenance, thereby minimizing costs.

Kubota’s extensive knowledge of battery materials enabled it to provide solutions suited to battery components’ unique specifications.

Kubota also maintained local service centers, thereby ensuring excellent after-sales service.

Solution

Product Demonstration and Easy Maintenance Wins Over Obstinate Management

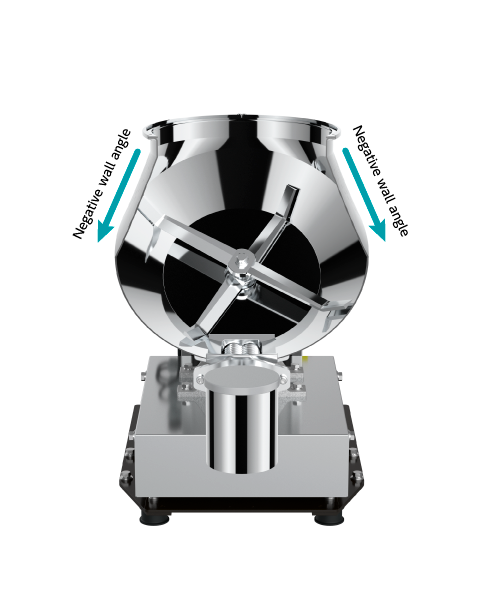

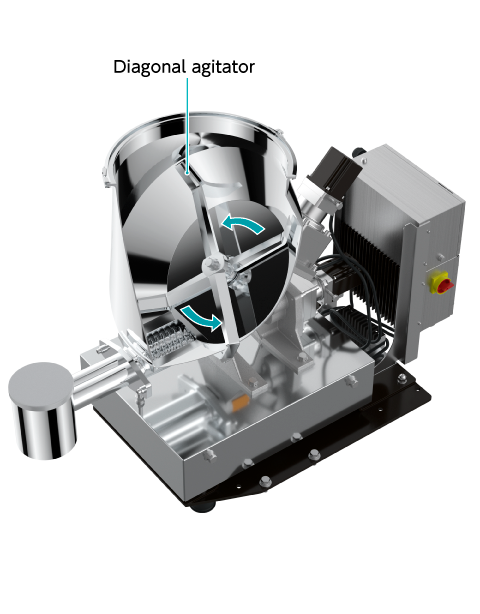

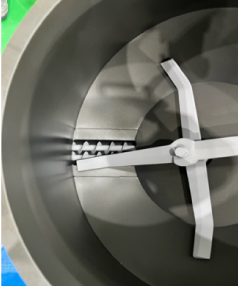

Still searching for a suitable feeder, the employee came across the NX series of gravimetric feeders on Kubota’s website. She immediately went about making enquiries, and presently a Kubota representative paid a visit with product information. The representative explained that Kubota’s NX series of gravimetric feeders feature a revolutionary design with an inverse tapered hopper and a diagonal agitator to prevent bridging and ‘ratholes’, thereby ensuring precise dosing and easy maintenance. The feeders’ simple design and small number of parts also reduced the number of maintenance personnel and spare parts that were required, suggesting the manufacturer would be able to minimize costs.

Furthermore, the team learned that Kubota possessed extensive knowledge on rechargeable battery components, and could provide solutions to their unique specifications, such as by swapping out feeder elements to suit the materials being fed.

Teflon coating inside hopper

Bolts changed to stainless steel

While the employee loved the NX series, which she felt had enormous potential, she would need more concrete evidence if she was to convince management. In response to a suggestion from an engineer, it was agreed that a test run would be performed at Kubota’s technical center.

“The NX series of gravimetric feeders was able to handle the materials we use with ease, and offered impeccable precision and operability. The small number of parts and simple design means the feeders are easy to disassemble and clean, and I could really appreciate how easy they are to maintain. Most importantly, Kubota has an in-country service center and offers excellent after-sales service, which I found reassuring,“ says the employee.

Based on her observations at the technical center and the feeder’s performance under testing, the employee made a proposal to management to purchase the NX gravimetric feeder. She explained that, rather than focusing on the unit purchase price, she wanted management to consider overall cost, including maintenance costs, assuming the need for stable operation. Management approved the proposal and agreed to replace Kubota feeders. The construction of the new factory is currently proceeding to plan, and the delivery of feeders and other production equipment is proceeding smoothly.

See solution details

NX-T

Twin Screw Gravimetric Feeder

Case Studies

Get insights into solving your company’s challenges

Resources

Download useful information and product catalogs