Case Studies

Micro gravimetric feeder eliminated premixing bottlenecks

Industry:

Plastics contract manufacturing

Department:

Production control

Summary of the solution

Kubota’s NX micro feeder eliminates the need for pre-mixing.

This gravimetric feeder remains accurate and reliable, even at very low flow rates.

Solution

Micro gravimetric feeder eliminated the need to premix

Team members started seeking information toward the issues. One day, a member of the team happened to mention the issues his team was experiencing with the premix process to an employee of a Japanese manufacturer in the same industry. He was informed that hardly any Japanese manufacturers premix additives anymore.

“I was really surprised when my colleague told me this. It’s true that for general applications, premixing can be eliminated by using gravimetric feeders. However, the processes that were causing us headaches all required micro-dosing. I just assumed there was no such things as a gravimetric feeder capable of precise and consistent micro-flow dosing,” says the staff member who is responsible for the manufacturing team. When he asked the Japanese manufacturer for more details, he was informed that Kubota’s NX series of micro feeders supported micro dosing. He decided to contact Kubota immediately.

Both productivity and accuracy were improved

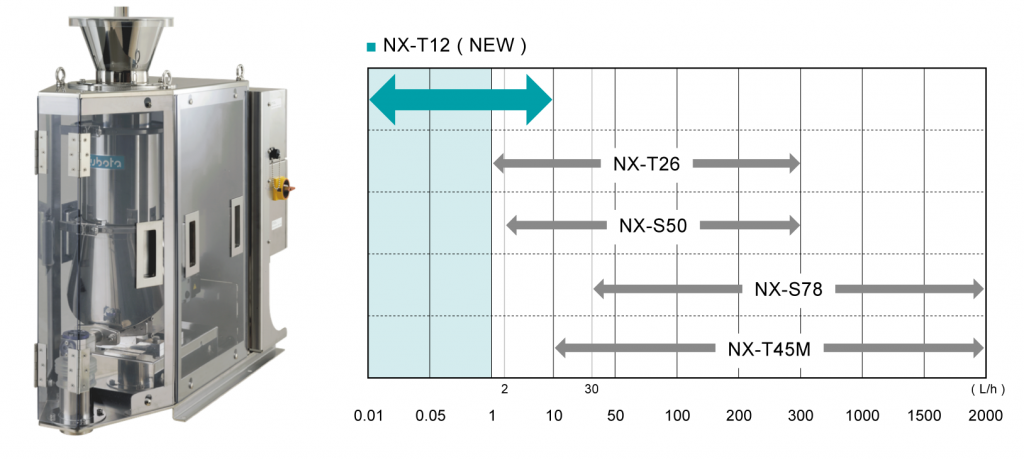

The NX range of micro feeders, while being gravimetric, are unique in that they provide an all-in-one micro-dosing solution that eliminates the need for premixing. The employee also learned that the NX feeders features three precision digital load cells, and are designed so that the weighing mechanism is enclosed in a draught-proof housing that prevents air currents from compromising accuracy. This design enables the feeder to dispense anywhere from 10 mL to 10 L/h while remaining highly accurate. In addition, the hopper’s negative wall angle design helps materials to flow more smoothly, making the feeder extremely resistant to bridging, with the result that materials are fulfilled to the screw consistently.

“Upon learning about the features of the NX micro feeder range, I realized it would be a good match for our challenges. My hope that this feeder would enable us to increase productivity while maintaining the accuracy that is so important for micro-dosing changed to certainty.” – production line staff member

After switching to the NX micro feeder, the manufacturer saw its productivity improve markedly due to the elimination of the premixing process, which took pressure off its production line. Reject losses were also virtually eliminated, and the manufacturer was able to handle increased volumes without the need to add another line or build another factory.

See solution details

NX-T12 / Micro Feeder

Twin Screw Gravimetric Feeder

Case Studies

Get insights into solving your company’s challenges

Resources

Download useful information and product catalogs