Classification of Powder

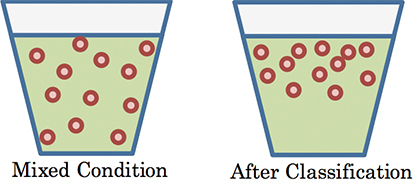

Classification is the phenomenon that ununiform particle in its size and bulk density get separated in hopper and feeding part. The phenomenon often happen to the material to be fed like pellet and powder mixed material, pulverized material and powder mixed material etc. In the field of analysis, we see the case the material are separated deliberately. However, for feeding process, the classification is not good because it changes the mixed material condition that was premixed appropriately in the previous process.

The problems caused by classification are the dispersion in accuracy by changing mixture consistence of material being fed. And also it might affect the product quality manufactured by extruder by getting mixed material condition worse. The classification is difficult to measure quantitatively, so it depends on sensory method like human eye check to measure the progress of classification.

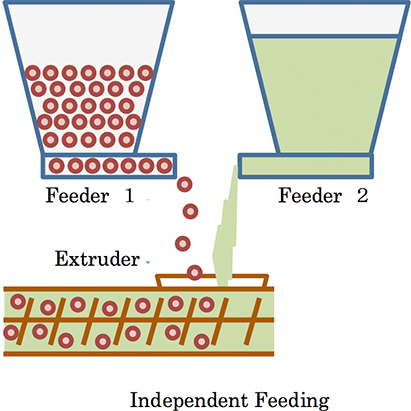

The classification is caused by the difference on speed of particles to be fed. Therefore, it is popular to lower the agitator rotation speed to control classification. It is advisable as fundamental way to resolve the issue that each material is fed independently by loss-in-weight feeder, instead of using premixed material.

SUMMARY

Classification of material is one of the most common issue in the plastic compounding process. Kubota can provide solution for appropriate material handling based on our experience and feeding technology cultivated for past 30 years.