Explosion Proof Zone Category and Dust Explosion Proof

We will introduce basic category and technology of explosion proof in this basics.

- Requirements for Gas Explosion and Dust Explosion

- Zone Definition

- Protection Code of Dust Explosion Proof

- Structure of Dust Explosion Proof Equipment

- Explosion Proof Approvals / Standards

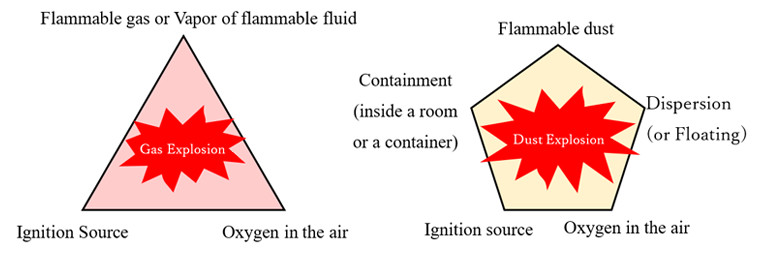

(1) Requirements for Gas Explosion and Dust Explosion

“Gas explosion” is caused when 3 elements, oxygen in the air, ignition source, and flammable gas or vapor of flammable fluid, are mixed. On the other hand, “Dust Explosion” is caused when 3 other elements, oxygen in the air, ignition source, and flammable dust filled inside a room or a container are mixed. Explosion-proof electrical equipment must be used not to fulfill these 3 requirements in order to prevent an explosion accident.

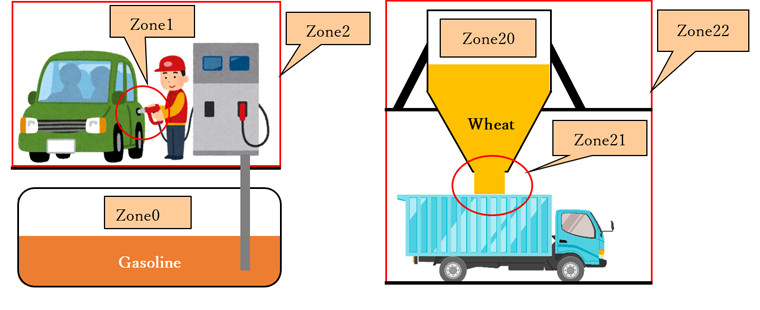

(2) Zone Definition

Hazardous area (potentially explosive atmosphere) is categorized by 3 zones depending on the explosive potentiality. Company which treats flammable gas or dust must select the proper explosion proof electrical equipment according to zone category guideline as below.

| Flammable Gas, Vapor of flammable fluid | Flammable dust | ||||

|---|---|---|---|---|---|

| Zone | Definition | Leak Frequency | Zone | Definition | Leak Frequency |

| 0 | An area that explosive atmosphere (mixing oxygen and flammable gas/vapor) presents continuously, for a long time, or frequently under normal condition. | Over 1000 hours per year | 20 | An area that flammable dust presents as dust cloud continuously, for a long time, or frequently under normal condition. | Over 1000 hours per year |

| 1 | An area that explosive atmosphere (mixing oxygen and flammable gas/vapor) presents occasionally under normal condition. | 10–1000 hour per year | 21 | An area that flammable dust presents as dust cloud occasionally under normal condition. | 10–1000 hours per year |

| 2 | An area that explosive atmosphere (mixing oxygen and flammable gas/vapor) presents rarely or very short time under normal condition. | 1–10 hours per year | 22 | An area that flammable dust presents as dust cloud rarely or very short time under normal condition. | 1–10 hours per year |

(3) Protection Code of Dust Explosion Proof

Inside Protection code starting with “Ex” is labeled on the each equipment. This mark defines the explosion proof performance of equipment.

Marking and definition of Equipment Protection Level

| Ex tc | IIIB | T90℃ | Dc | |

|---|---|---|---|---|

| Explosion Proof Structure | Group of Explosion Proof Electrical Equipment | Temperature Class | Protection Level | |

| Protection by enclosure “t” | Ex ta | IIIA: Flammable fibers Dust of particle size over 500μm IIIB: Non-conductive dust with electrical resistivity Dust of particle size 500μm or less and electrical resistivity over 1000Ωm IIIC: Conductive dust with electrical resistivity Dust particle size 500μm or less and electrical resistivity 1000Ωm or less. |

Maximum surface temperature (Add “T” at the beginning of the figure) |

Da (Zone20) Db (Zone21) Dc (Zone22) |

| Ex tb | ||||

| Ex tc | ||||

| Intrinsically safe “i” | Ex ia | |||

| Ex ib | ||||

| Ex ic | ||||

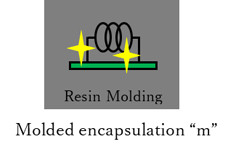

| Protection encapsulation “m” | Ex ma | |||

| Ex mb | ||||

| Ex mc | ||||

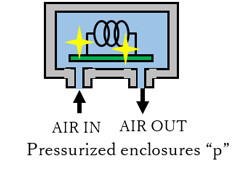

| Pressurized apparatus “p” | Ex p | |||

In zone22, higher ranked equipment like Zone 20(Da) or zone21(Db) are available to be used.

(4) Structure of Dust Explosion Proof Equipment

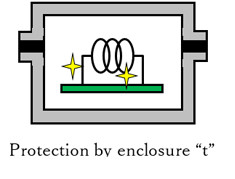

Protection by enclosure “t” – Enclose electrical circuit in the tightly closed container that dust are not able to come in.

Protection by enclosure “t” – Enclose electrical circuit in the tightly closed container that dust are not able to come in.

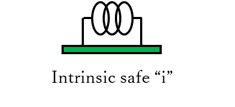

Intrinsically safe “i” – Electric spark which might be generated from electric circuit is limited within a certain range of voltage not to ignite in the gas or dust atmosphere.

Intrinsically safe “i” – Electric spark which might be generated from electric circuit is limited within a certain range of voltage not to ignite in the gas or dust atmosphere.

Molded Encapsulation “m” – Enclose the electrical circuit in insulation resin molding.

Molded Encapsulation “m” – Enclose the electrical circuit in insulation resin molding.

Pressurized enclosures “p” – Enclose the electrical circuit in container purging air or N2 gas in order to prevent flammable gas or dust moving inside.

Pressurized enclosures “p” – Enclose the electrical circuit in container purging air or N2 gas in order to prevent flammable gas or dust moving inside.

*These explosion proof structures except enclosure “t” is used for not only dust explosion proof but also gas explosion proof as well, so the user must pay attention to the indication of “group” (II = gas, III = Dust) or “protection level” (D = dust, G = gas) to identify the category of the explosion proof, gas or dust.

(5) Explosion Proof Approvals / Standards

Electrical explosion proof equipment are examined its explosion proof performance by the testing and certification organization. The explosion proof equipment can be used after it pass the examination and it is certified explosion proof by the organization with issuance of certificate documents. Chinese, Korean, and Taiwanese explosion proof is basically abide by IEC, the International Electrotechnical Commission. However the equipment that which meet local regulation must be used. Local standard and certification organization in each countries in Asia is shown as below.

| Country | Standard | Verification Body |

|---|---|---|

| JAPAN | Standard Structure and IECEx | TIIS, DEKRA |

| CHINA | GB | NEPSI |

| KOREA | KS | KOSHA |

| TAIWAN | CNS | ITRI |

SUMMARY

Kubota have wide range of product line up of gravimetric feeder including explosion proof type. If you are interested, please contact REP in your region.