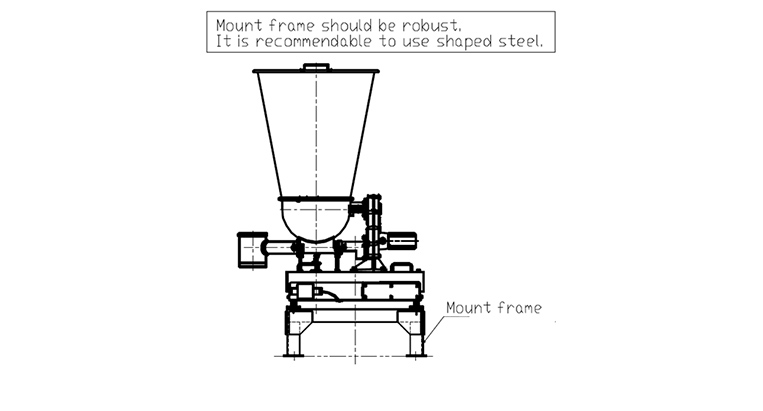

Feeder Mount Frame

There are some important points to consider to install Gravimetric Feeders to bring out its best performance. The major concern is that Gravimetric Feeder is a kind of precise weighing equipment needed to be carefully handled. Let’s see what is important.

(1) Kinds of Mount Frame

(1) Independent Feeder Mount Base

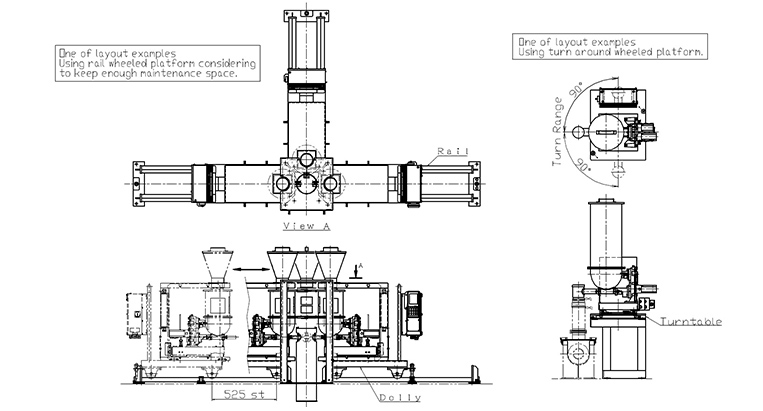

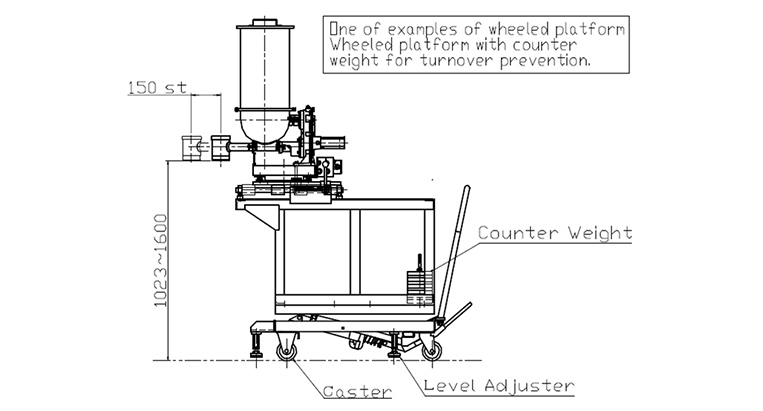

To adjust installation height, various types of wheeled platform for maintenance purpose like caster wheel type, rail type, turn table type etc.

(2) Common stage for multiple number of feeders

Middle level stage etc.

(2) Points to note to design mount frame

(1) Because gravimetric feeder is a precision weighing equipment, mount frame should be robust. It is recommendable to use shaped steel.

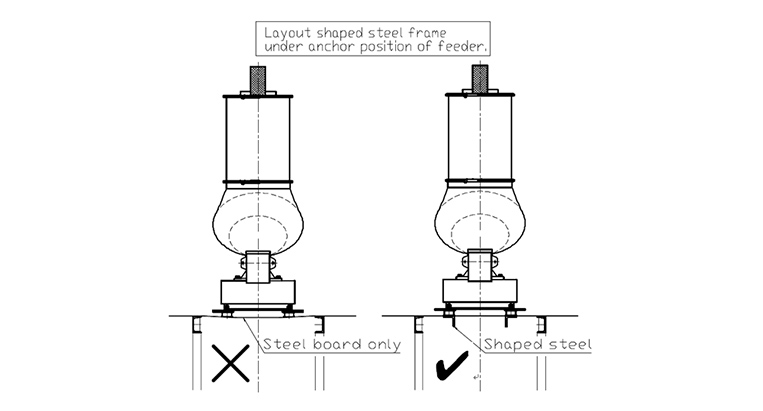

(2) Layout shaped steel frame under anchor position of feeder. In case feeders are installed on steel board without frame, feeders are easy to move up and down, which consequently lead to unstable weight and inconsistent feeding control. Insufficient strength of mount frame makes feeders move up and down, the weight signal become unstable even when the feeders are connected with upstream and downstream device by canvas.

(3) Enough space for maintenance work of feeder need to be considered. Design layout of feeders for easy maintenance work to remove and replace belt for Belt Weighing Feeder, and hopper, screw, agitator for Loss in Weight Feeder. In case multiple number of feeders are closely placed, it is recommendable to adopt wheeled platform, rail wheeled platform and turn table type for maintenance work purpose. Level adjuster should be equipped with wheeled platform.

(4) It should be avoided that feeders are installed in overhang place, because it is unstable. In case of unavoidable circumstances, please consider to take sufficient countermeasures like safety against overturning, placing counter weight etc.

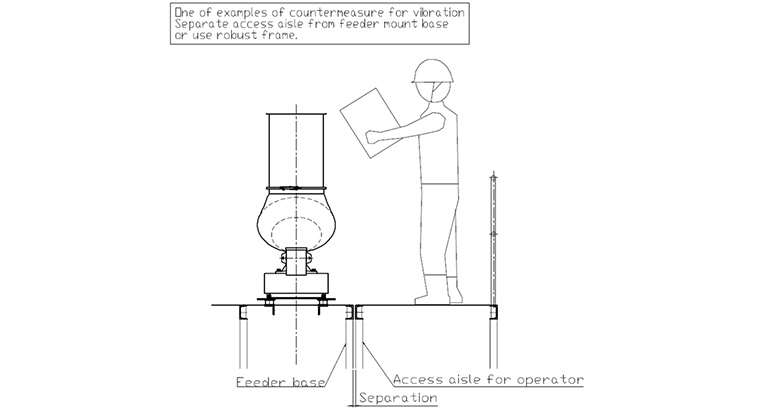

(5) Not to vibrate feeders when a worker walk around. Especially Loss in Weight Type feeders tend to be sensitive against low frequency vibration. It is sometime seen that the reason of unstable feeding is caused by vibration when a worker access to feeder to refill material manually. As a countermeasure, separate access aisle from feeder mount base or use robust frame.

(6) In case feeder stage is placed in-between 1st floor and 2nd floor, it is recommendable to make stage on the 1st floor, not to hang it down from 2nd floor, because it is stronger against vibration.

(3) Others

(1) Feeders should be installed under the condition that the amplitude of vibration is less than 100μm, and the frequency is less than 30Hz.

(2) In case vibration source like mixer is close to feeder or the frame base is not strong enough, it causes unstable weight and inconsistent feeding control. As countermeasure, please place feeder and vibration source separately or reinforce mount stage by adding extra frame, especially just under the feeder is installed. Before considering to take action to prevent feeder vibration, it would be more effective to prevent vibration of its direct cause.

(3) When feeders are transported, please be sure to install attached bracket to prevent damage to load cells.

SUMMARY

Based on past long experience, Kubota can provide appropriate advice how to install Gravimetric Feeder. And if you have any trouble on feeder installation condition, please contact us to fix that problem.